Last week I had the opportunity the Infor Velocity Days event held in Orlando. Overall, I was very impressed with the quality of the information presented and the knowledge that the guest speakers brought to the table. Two sessions that really resonated with me dealt with the question How far off of typical are your processes, and The Hidden Cost of Customizing Your ERP System. Full disclosure: I’ve lived through the nightmare of a system held together by workarounds and bad data, and I spent a lot of time cleaning it up. This topic is close to home for me.

Most distributors believe their processes are unique. Some even take pride in it. The truth is usually less flattering. Many “unique” processes are not strategic at all. They are the products of old limitations, past employees, or system restrictions that no longer exist. Over time these differences harden into habits, workflows, and in some cases, full‑blown ERP customizations.

The problem is not that distributors do things differently from one another. The problem is that most companies no longer know why they do things differently. At that point, the process stops being an advantage and turns into something else entirely. It becomes technical debt.

And that debt gets expensive.

How processes drift

Process drift is rarely intentional. It happens slowly. A team makes a small workaround. Then another. Someone adds a new step to avoid a past mistake. A manager plugs a gap by reassigning work to a different role. Someone builds a spreadsheet to “help” the ERP. A key employee leaves and their tribal knowledge gets baked into the next workaround.

After a few years the workflow on the floor barely resembles what the ERP thinks should be happening. The company assumes this is normal because it works “well enough.” The danger is that no one realizes how far the process has drifted from both the system design and industry best practice.

Once drift goes far enough, technology must bend to accommodate it. That is when customizations begin.

Customizations are comfortable at first

Most customizations start with good intentions. A team wants to speed up a task or reduce errors. A supervisor wants to configure the system to match the way work is being done today. A vendor or consultant is happy to build whatever the company asks for.

The fix works. At least for a while. The real cost shows up later.

Every customization you layer into an ERP creates one more dependency that has to be maintained. One more rule that has to be tested. One more item the next upgrade has to work around. One more reason the business cannot adopt new best practices without breaking something that was glued together five years ago.

The worst part is that many of the customizations no longer solve a meaningful problem. They were built to support a process that should have been retired years ago.

How much does “unique” really cost?

When distributors calculate the cost of their processes, they tend to focus on labor. They rarely account for:

- The cost of maintaining custom code

- The cost of delaying upgrades

- The cost of supporting tools that only one person understands

- The cost of training new hires on homegrown workflows

- The cost of lost automation because the system cannot revert to standard logic

- The cost of manual checks that exist only because of old workarounds

None of these numbers show up on an income statement, but they are real. They accumulate quietly. Eventually the company finds itself saying things like, “We cannot upgrade this year,” or “That feature does not work for us,” when the real issue is not the ERP. The real issue is ten years of drift.

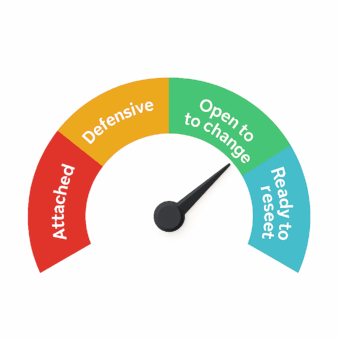

The emotional attachment is real

This part deserves more attention. People grow attached to the way things work today. They helped build the current process. They shaped it. It feels familiar. It feels safe. Even when a better way exists, teams will defend the familiar one because it is tied to their identity and history.

This part deserves more attention. People grow attached to the way things work today. They helped build the current process. They shaped it. It feels familiar. It feels safe. Even when a better way exists, teams will defend the familiar one because it is tied to their identity and history.

This human element is one of the biggest blockers of operational improvement. It is not technical. It is cultural. And until leaders acknowledge it, they cannot address it.

A useful question to ask your own team is straightforward:

How in love are you with your current processes?

If the answer is “very,” you already know where the resistance will be.

A more objective way to evaluate your processes

The good news is that the industry finally has tools that give distributors an honest view of their real workflows.

- Process mining can show the actual path users take.

- Benchmarks reveal how far your version is from what others in the industry do.

- Decision trees and rules engines make it clear where logic has drifted.

- Workflow tools expose bottlenecks that were invisible before.

You do not need perfect documentation to start. You just need data. Once you have an accurate map of how work really happens, decisions become clearer. The question shifts from “What are we used to?” to “What actually works best?”

The path forward

Resetting processes is not an indictment of the past. You made decisions that worked at the time. The goal now is to decide whether those decisions still make sense. Some processes will stay. Others will need to be aligned with standard workflows or rebuilt from scratch.

As the industry becomes more automated, process discipline becomes a competitive advantage. The companies that thrive will be the ones brave enough to ask the uncomfortable questions. They will not cling to the past. They will evaluate the cost of difference honestly and decide where it still creates value.

Everything else is friction.

This article was shaped in part by the conversations and breakout sessions at last week’s Infor Velocity Days event in Orlando. I want to thank Brandy Alderman, Jeffrey Baily, Max Fisher, Shelley Horn, and Aaron Roma for the insights they shared throughout the week. Their perspectives on process alignment, modernization, automation, and distributor workflows helped reinforce many of the themes explored here. I would also be interested in hearing what your experience has been with ERP customizations in your own organization and how they’ve helped (or held back) your operations.

Leave a Reply