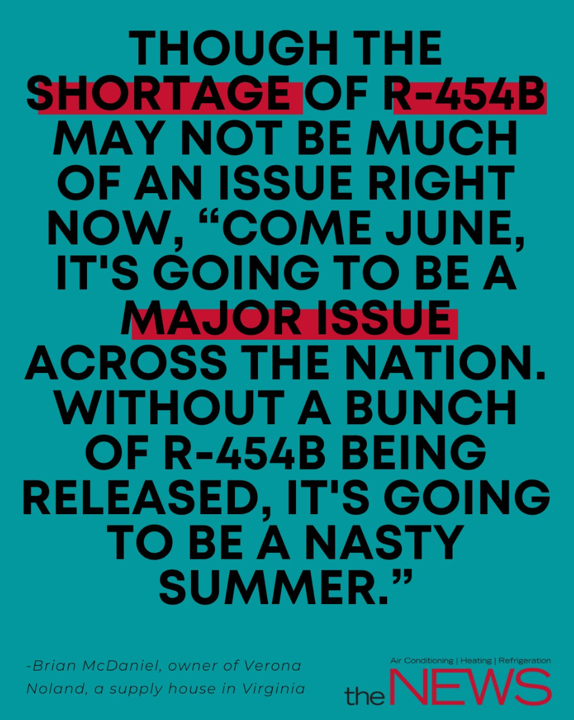

Guess what? Brian was right. It’s June and the R-454B shortage is here.

Recently, I tuned in to HARDI’s webinar titled “Mixing Refrigerants: Addressing Misinformation and Best Practices,” hosted by Talbot Gee, CEO of HARDI, and featuring Mike Breen of Rheem/Ruud, who also serves on NATE’s Technical Committee. It was a timely, no-nonsense discussion about the challenges surrounding A2L refrigerants—especially R-454B—and how those challenges are playing out in the residential HVAC market. Mike brought real technical clarity, and Talbot did a great job framing the business context for distributors and rep agents.

Takeaways on Mixing Refrigerants

I wanted to share my key takeaways from the session—particularly around the nature of the refrigerant shortage, what to communicate to your contractor customers, and how reps and distributors can guide their teams through this transition successfully.

Understanding the Nature of the Shortage

The current shortage of R-454B isn’t due to one big failure. It’s the result of several overlapping issues hitting all at once:

- Faster-than-expected demand, especially in southern markets

- Supply chain bottlenecks related to cylinder availability and packaging infrastructure

- OEM and distributor forecasting gaps

- Limited field readiness for safe A2L refrigerant handling

Interestingly, the refrigerant itself is not the issue—OEMs can access it for equipment production. The real constraint is getting it safely packaged and delivered to the field in certified A2L cylinders. This mismatch has led some techs to take shortcuts—specifically, mixing R-410A or R-32 into R-454B systems—and that’s where the real damage begins.

What to Tell Contractors: Never Mix Refrigerants

One of the most important themes from the webinar was clear: mixing refrigerants is a bad idea—legally, technically, and commercially.

Here’s what your contractor customers need to know:

- It’s illegal and unsafe. Mixing A2L and A1 refrigerants creates unknown flammability and pressure risks.

- It voids certification and likely the warranty. Once off-spec, that unit is no longer UL-certified and the liability shifts to the installer.

- Performance will suffer. Even if the unit “runs,” it won’t meet the SEER2 ratings or deliver reliable comfort.

- It leads to expensive callbacks. And possibly complete refrigerant recovery and destruction—meaning wasted time, gas, and money.

If a system has mixed refrigerants, it must be fully recovered using an A2L-rated recovery tank, purged with nitrogen, vacuumed, and recharged with fresh R-454B. No shortcuts.

What Distributors Can Do Right Now

Distributors are under pressure from all sides—contractors want product, OEMs want compliance, and the supply chain is strained. But there’s still room to lead.

Key steps:

- Tie refrigerant to equipment. Prioritize R-454B availability for system installations, not general service.

- Help plan line set charges. Educate contractors on calculating how much additional refrigerant they need based on line length before the install.

- Reinforce reclaim discipline. Mixing destroys valuable 410A, which will become harder to find. Help contractors preserve clean reclaim by not mixing gases.

- Be the voice of truth. Misinformation spreads fast. Share insights from OEMs, HARDI, and NATE to give contractors confidence in what’s right.

If you offer training, make sure it includes knowledge verification. Passive webinars won’t change behavior, but accountability will.

How Rep Agents Can Lead the Conversation

Rep agents have a unique opportunity to provide practical, field-level leadership during this transition. Distributors and contractors alike are looking for clarity—and reps can deliver it.

Here’s how:

- Facilitate quick, targeted trainings on A2L safety, charging best practices, and commissioning standards.

- Push documentation culture. Encourage techs to track refrigerant type, weight, and performance metrics. Share frameworks like ACCA’s quality install program.

- Be a channel translator. Help contractors understand what OEMs are asking for, and help OEMs understand what’s actually happening in the field.

- Reinforce value. Remind everyone that “doing it right” creates a competitive advantage—and helps protect the brands you represent.

Shortage = Temporary. Mistakes = Permanent.

Everything we’re hearing suggests the R-454B shortage is temporary—but the consequences of cutting corners will be long-lasting. Contractors may feel squeezed, but that doesn’t justify risky installs or poor refrigerant handling. Those choices carry real liability, not to mention performance issues and safety risks.

This is the time for distributors and reps to step up—not just with product, but with leadership, education, and clarity. That’s how you build loyalty with contractors and protect your market position when the transition dust settles.

As Talbot Gee said in closing, “Let’s focus on the things we can control.” For distributors and reps, that means consistent messaging, smarter planning, and helping your contractors do the right thing—especially when it’s hard.

Reader Input – Major industry changes inevitably have hiccups that take time to smooth out. We’d like to know your thoughts on your company’s preparation to this change through this 4 question distributor survey. Aggregated input will be shared in an upcoming article and a report will be available.

Leave a Reply