In June HVACRTrends hosted a webinar introducing the Trimble / Distributor Data Solutions (DDS) collaboration. The two companies shared what they are seeing in the construction trades and how data is being used, and will be used, to help companies operate more efficiently, more effectively, and as a tool to capture market share.

Takeaways

Two key takeaways from the session were:

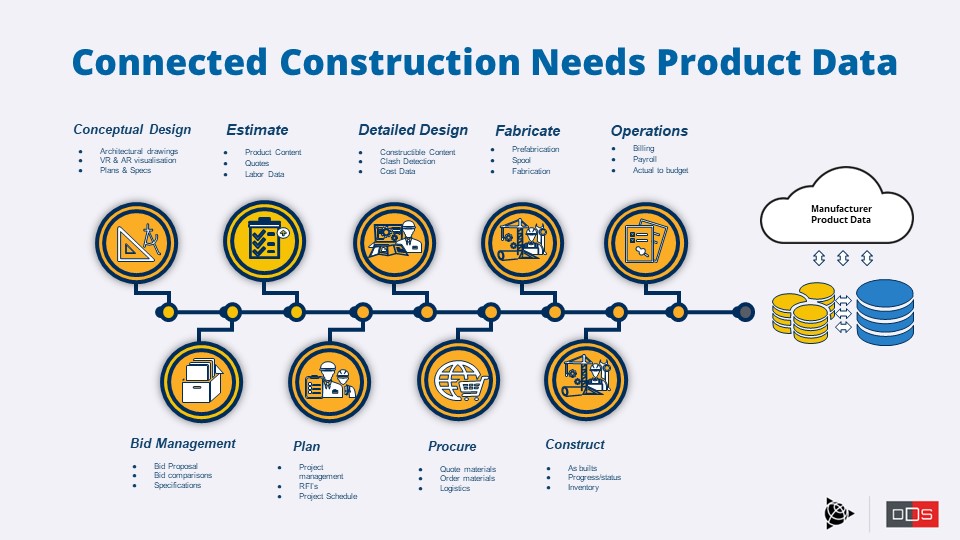

- Trimble, which has extensive experience in the design and construction markets, shared the typical contractor workflow. Gaining a broader perspective of a contractor’s workflow and how “data” is integrated into every aspect. Gaining data continuity from the manufacturer, through the distributor (ERP and eCommerce) and into contractor systems will help improve channel efficiency, reduce operational costs, and improve customer experience in finding (and recommending) products. This chart highlights the workflow.

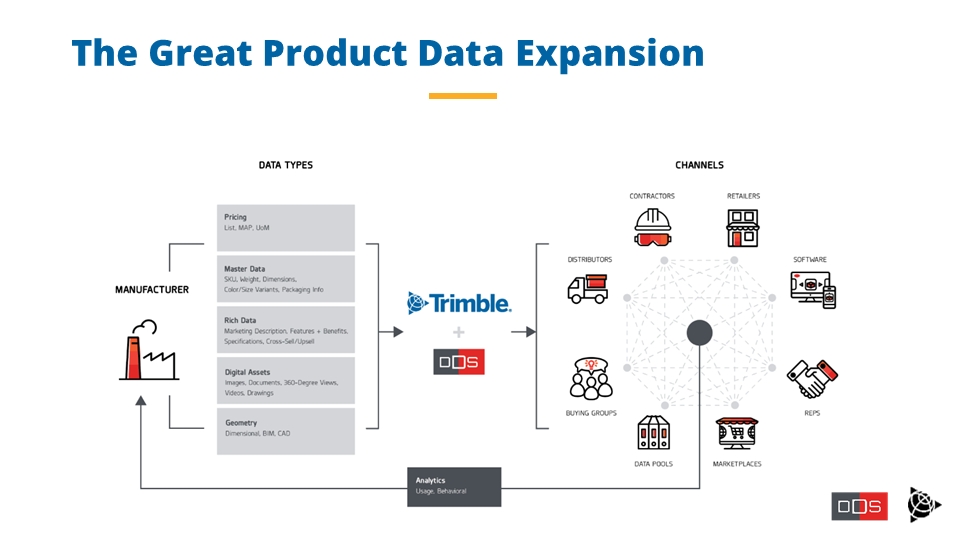

- Matt Christensen from DDS shared what they are seeing relative to data trends and how the term “data,” which was historically segmented as ERP and eCommerce, is now much more. The chart to the left highlights elements of the data (right side of the slide) and where the data is being disseminated within a manufacturer’s channel as well as distributed within distributors via PIM systems. Clean, consistent, and robust data is helping leading distributors achieve new heights.

Additional highlights from the session included:

- “ERP” is thought of as the tools that distributors, manufacturers, contractors, industrial facilities, municipalities, engineers, and architects use in managing their business, processing orders, and managing their inventory. But the “E” really is an ecosystem and it is the system that needs quality manufacturer product data.

- They overviewed the new partnership between the companies that combines the deep history and relationships on the Trade Service and Trimble side, and the disruptive thinking about how to efficiently move “data” that DDS brings to the market.

- Patrick Walker, Director of Product Management for Trimble, talked about mastering product data. He shared how far data goes through the ecosystem, how contractors use connected data today, and where product data ends up in their workflows.

- The simplified flywheel is that product market data is provided to syndication partners, who create structured data and enrich the data. We take that data and structure and enrich the data, which is important for getting various jobs done throughout the industry.

- The digital supply chain is the process of turning digital data into real products. It starts with an idea in someone’s head, gets refined and detailed into an actual product, and then turns into a real product with cost and a real product that actually can be constructed.

- The two companies commented that they are seeing more and more data types flow from manufacturers to their entire channel with the information being used for rebates, SPAs, translations, warehouse optimization, logistics, certifications globally for supply chain, geometry, BIM models, CAD, and full life cycle of building.

- The number of channels, content needs from the channels, distributors’ needs are increasing all the time, and new niche marketplaces are popping up all the time around all industries. Retailers are also leading the way for new types of product data, and the product content being used.

- Trimble and DDS are going to provide analytics from the entire channel to manufacturers on what the channel’s doing, giving valuable insights, giving you ROI on all that money being spent on product data creation and syndication.

- Hunter Wagner, Global Product Marketing Lead for Trimble, shared the direction Trimble thinks product data in the construction trades is going. He commented that we’ll be thinking of digitalization in the construction channel as connected workflows. He stated it all starts with a shipping container of documentation and ends with a process that turns that into an MRO catalog for an owner.

- The market is changing around connected construction, and you’ll see it in what the market is demanding. There is also an age shift, with younger folks increasing responsibilities within contracting companies. The data required by these systems is going to be much more structured and detailed than the past, and it’s going to have to travel farther and faster, be much more portable and consumable by different systems.

- The connected construction workflow is going to require data in a lot of different formats, and there’s going to be a lot of technology that’s going to drive how the traditional data sits. Manufacturer product data is going to be essential to this workflow.

- The model informs the estimate and vice versa, synching this data all the way through the procurement process into the product management and ERP system, enabling super powerful decision Artificial intelligence’s emergence in construction will be able to leverage this data to an even more powerful effect.

- Trimble’s partnership with DDS links cutting edge content management technology with an industry leading distributor and contractor network … 7,000 plus distributor locations, 13,000 estimating desktop users across electrical and mechanical, 3,000 modeling users, and even field solutions that leverage model data that includes manufacturer products. .

- Matt Christensen from DDS shared:

- Manufacturers are deciding to own their data and are letting the network effects of the market pull their data into the market. This gives them more control over how their data is syndicated, shown, and featured. At the end of the day, it’s out in the market, and customers are having a “user experience” with your product data. Understanding that and taking ownership is a very powerful thing.

- Analytics can be used to audit how data is used in the ecosystem and provides a feedback loop to make sure manufacturers really own their data.

- There are lots of opportunities for automating for efficiency on the distributor side, and this creates less overhead and less data errors, and ensures storefronts have rich content.

- The distributors we see that are really at the forefront of the industry are embracing technology and building themselves, partnering with other companies, and combining these three into providing the best-in-class capabilities to their actual clients.

- The completeness of the data is important, and I think that’s one of the things we’re going to bring: standardized industry specific data analysis.

- The session concluded with Q&A from the audience that covered topics including:

- Manufacturers and distributors are investing billions of dollars in digitalization over the next four or five years but are wondering whether this is limited to the big distributors or only the big contractors.

- How smaller distributors and manufacturers can benefit from having enriched product data.

- What questions should they be having their salespeople ask their customers?

- What are best practices for manufacturers to pull data together internally given that they have a number of systems with different information in them?

- What is a good definition of “data quality?”

Click here to view the webinar

Click here to learn more about Trimble Construction Content and DDS